The importation of packaging bags is a crucial aspect of the supply chain. Using third-party inspection services is one of the key strategies usually employed by importers to ensure the quality and compliance of packaging bags. Because businesses seek to source cost-effective and high-quality packaging solutions from different parts of the world, the need for stringent quality control measures becomes paramount. In this article, we will delve into the significant role that third-party inspection services play in maintaining quality standards and mitigating risks when importing packaging bags.

Because packaging quality holds significant importance, the importers find it imperative to use Third-Party Inspection services

Packaging plays a pivotal role in protecting and preserving products during transportation, storage, and display. Whether it’s food, pharmaceuticals, or consumer goods, the integrity of packaging is directly linked to the safety and quality of the enclosed products. Importers understand that substandard packaging not only poses risks to the products but also jeopardizes the reputation and credibility of their brands.

Challenges in Importing Packaging Bags:

Importing packaging bags comes with challenges, including variations in manufacturing standards, differences in material quality, and adherence to regulatory requirements. Without proper oversight, importers may face issues such as defective packaging, inconsistent product quality, and non-compliance with international safety standards. To address these challenges, many businesses turn to third-party inspection services as a proactive measure.

The Role of Third-Party Inspection Services:

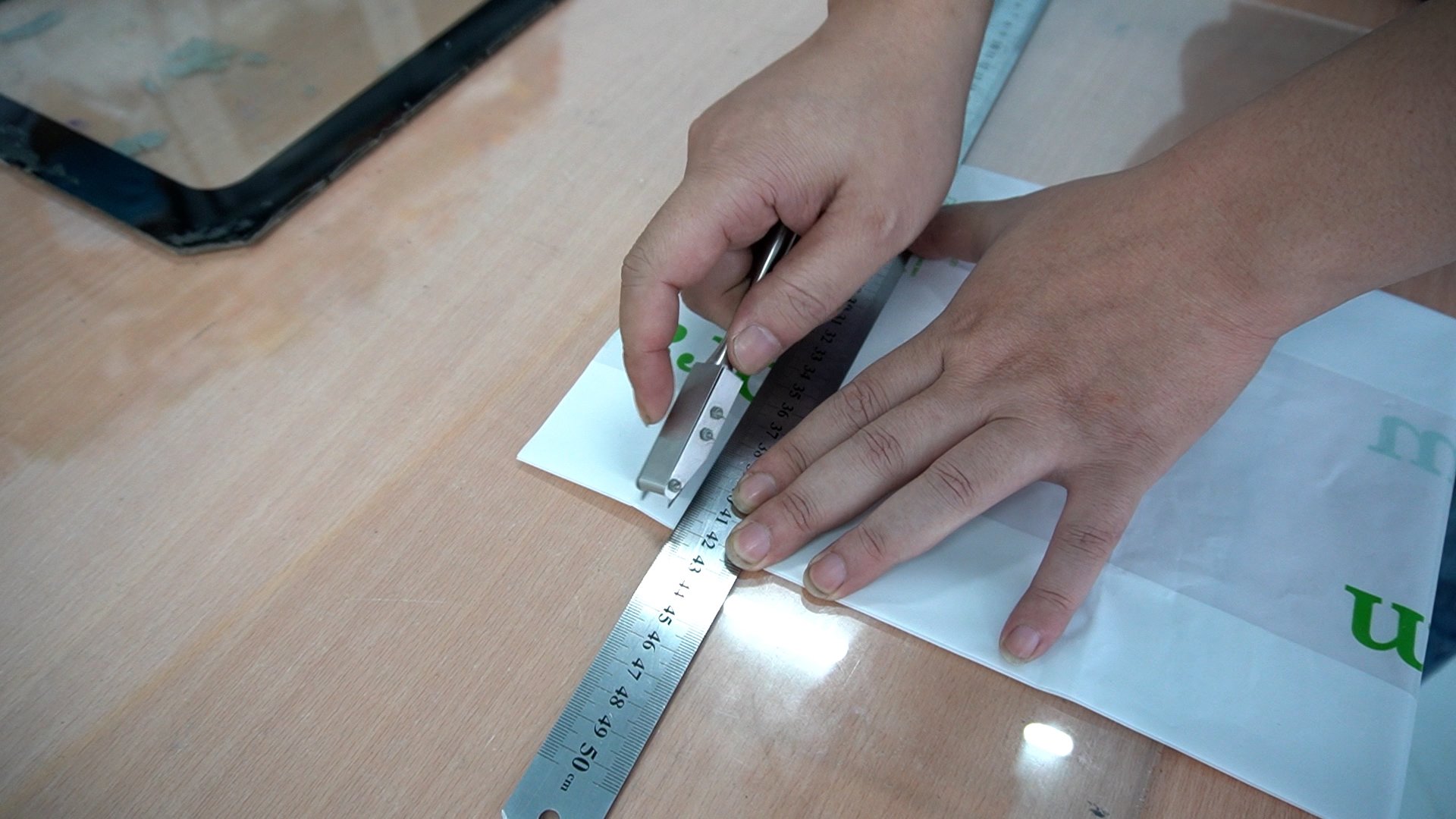

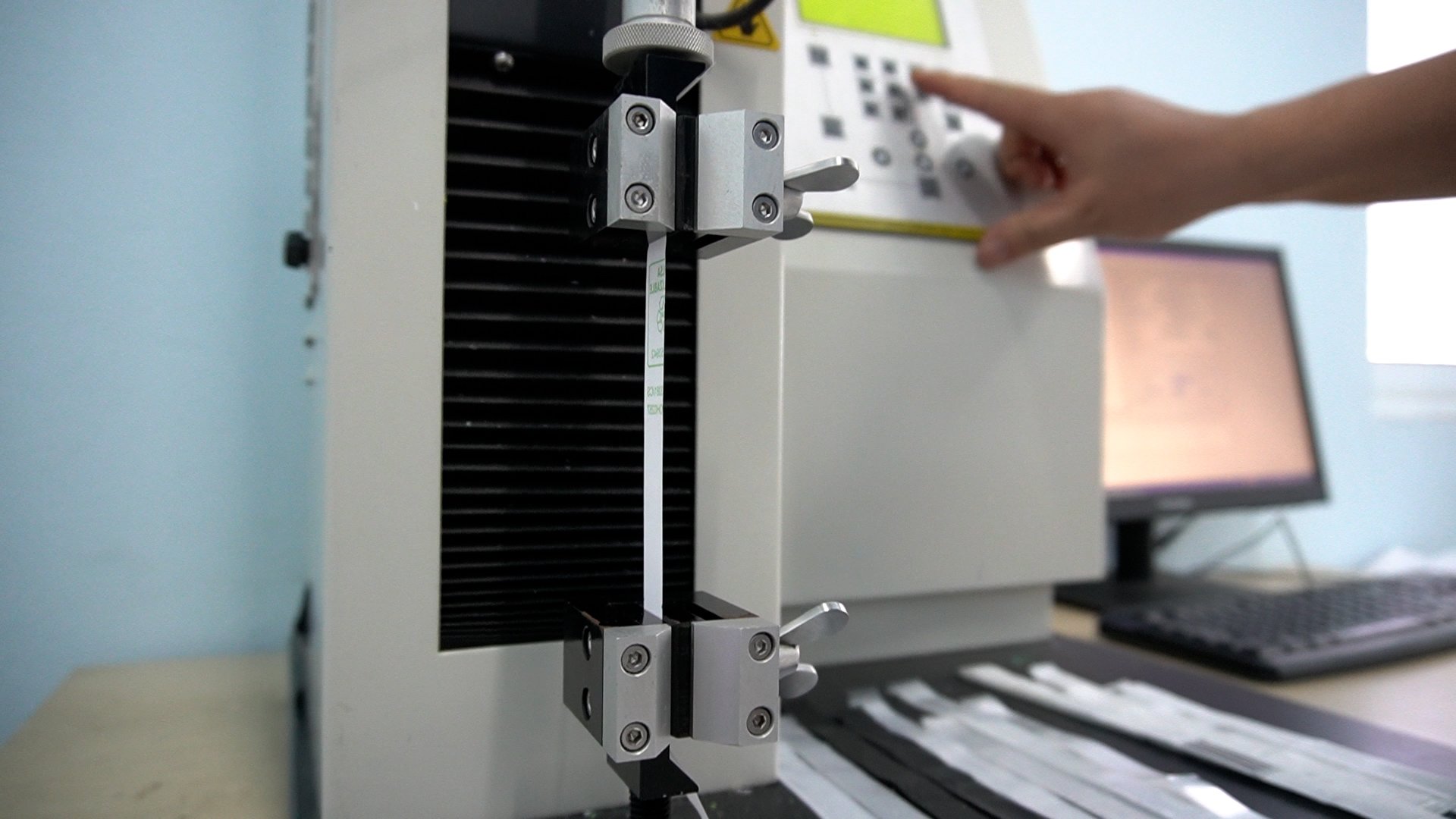

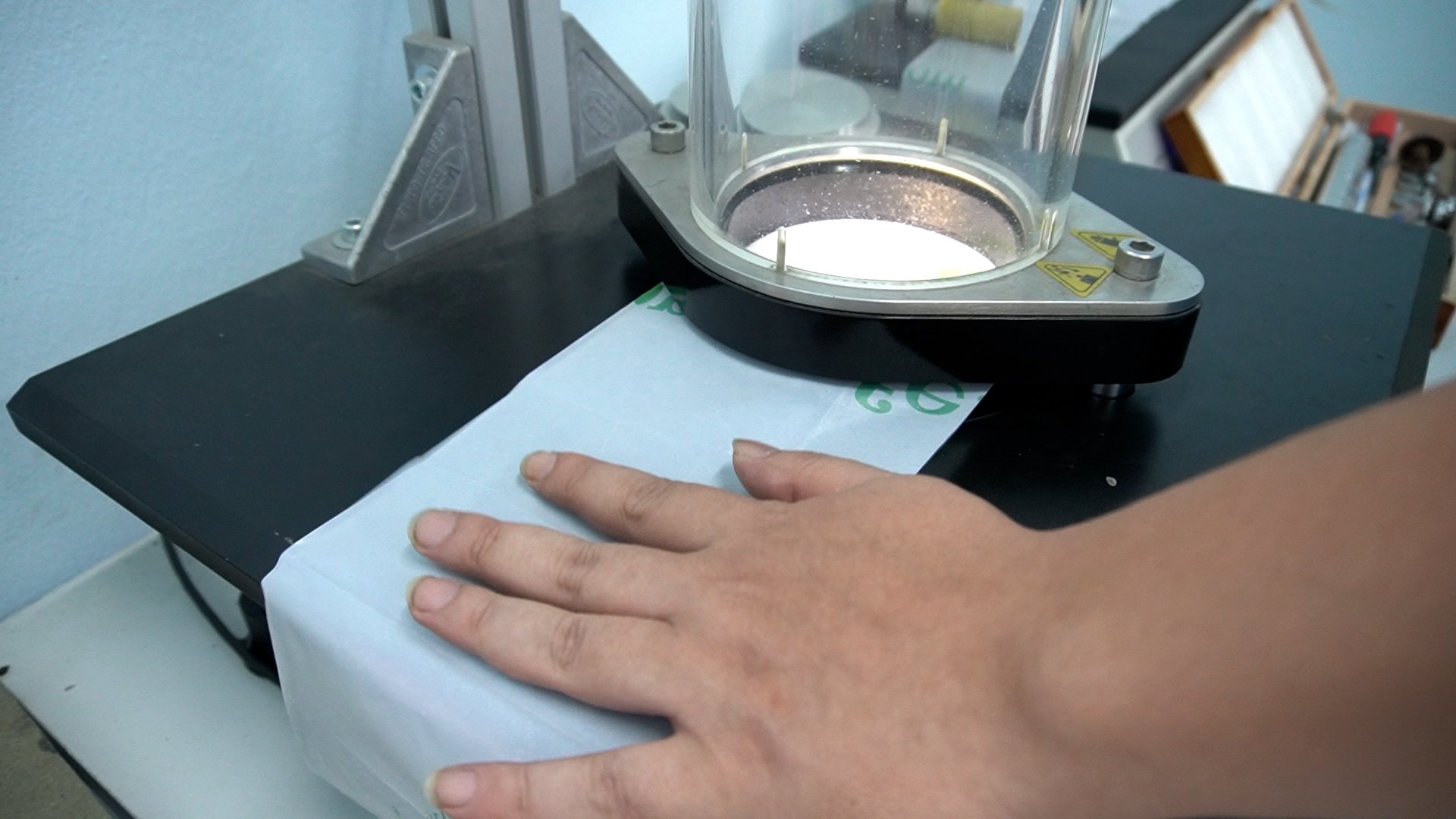

- Quality Assurance: Third-party inspection services act as independent entities that assess and verify the quality of packaging bags before they are shipped to the importer. This includes scrutinizing the materials used, evaluating the manufacturing processes, and ensuring that the final products meet the specified quality standards. Through comprehensive inspections, importers can identify and rectify quality issues early in the production process, minimizing the risk of receiving substandard goods.

- Compliance with Standards and Regulations: Packaging regulations and standards vary across countries and industries. Third-party inspection services are well-versed in these regulations and can confirm whether the packaging bags comply with local and international standards. This includes assessing factors such as material composition, labeling requirements, and environmental considerations. Ensuring compliance is not only essential for product safety but also for avoiding legal complications that may arise from using non-compliant packaging.

- Supplier Evaluation and Selection: Before entering into agreements with suppliers, importers can engage third-party inspection services to evaluate the capabilities and reliability of potential partners. These services conduct supplier audits, assessing factors such as production facilities, quality control processes, and adherence to ethical and environmental standards. By making informed decisions based on these evaluations, importers can establish strong and reliable partnerships with suppliers committed to delivering high-quality packaging products.

- Risk Mitigation: Third-party inspection services play a crucial role in risk management. By identifying and addressing potential issues early in the production process, importers can mitigate the risk of receiving defective or non-compliant packaging bags. This not only protects the importer’s investment but also safeguards the interests of end consumers who rely on the integrity of the products they purchase.

- Cost Savings: While there is a cost associated with hiring third-party inspection services, it can be a cost-effective measure in the long run. Identifying and rectifying quality issues early can save importers from having to deal with costly product recalls or returns.

- Objective Evaluation: Third-party inspectors provide an unbiased and objective evaluation of the products. This objectivity is crucial in assessing quality and compliance without any conflicts of interest that may arise when relying solely on information provided by the supplier.

- Improved Communication: Inspections provide a clear and standardized means of communication between the importer and the supplier. Any discrepancies or issues can be documented and communicated effectively, facilitating resolution.

- Customer Satisfaction: Ensuring the quality of packaging bags through third-party inspections contributes to customer satisfaction. High-quality packaging reflects positively on the overall product and brand reputation.

In the competitive global trade landscape, the importance of quality assurance in packaging cannot be overstated. Importers of packaging bags face multifaceted challenges that demand proactive and thorough solutions. Third-party inspection services emerge as indispensable partners in this process, offering a comprehensive approach to quality control, compliance verification, and risk mitigation. By leveraging these independent entities’ expertise, importers can confidently navigate the complexities of international trade, ensuring that the packaging bags they import not only meet but exceed the expectations of both regulatory authorities and end consumers.